In order to always provide high quality chlorella

In order to always provide high quality chlorella, we are committed to quality, from the culture environment to the manufacturing methods.

In addition, in order to provide safe products, we conduct our operations with safety as our top priority.

Two points that we focus on in order to provide high-quality chlorella

1. Focus on strains

There are various species and strains of chlorella, each with different cell capabilities and nutritional components. We studied the strains that grows best in the production area and have the best nutritional content. As the result, we have selected Sun Chlorella strain (chlorella pyrenoidosa species).

There are various species and strains of chlorella, each with different cell capabilities and nutritional components. We studied the strains that grows best in the production area and have the best nutritional content. As the result, we have selected Sun Chlorella strain (chlorella pyrenoidosa species). Chlorella contains variety of ingredients, and the most valuable one among them is C.G.F. (chlorella growth factor). C.G.F. also known as “chlorella extract”, is an ingredient that was discovered during the research process for its growth-promoting effect on lactic acid bacteria and has attracted attention. Sun Chlorella also standardizes and manufactures C.G.F.

2.Focus on environment where chlorella grows

We are committed to cultivating our plants outdoors, as close to the natural environment as possible, and where they can receive sufficient energy from the sun. Outdoors culture allows chlorella to obtain more useful ingredients such as vitamin B12 and C.G.F. than tank culture without sunlight. This is why chlorella is called “canned sunshine”. However, for outdoors culture requires lots of conditions such as a climate with little rain, plenty of sunlight, and stable temperature (average temperature of 20 degrees or higher), pure water, clean air and etc. In japan, we can’t find the suitable place to meet these conditions excepting limited area in the south. Thus, Sun Chlorella produces high-quality chlorella with outdoor cultivation at a facility in Taiwan that meets the conditions and has a long production history.

A reliable and high technical ability that achieves high digestibility of chlorella

Focus on strains

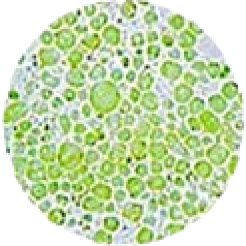

Since its birth 540 million years ago, chlorella has survived severe environmental changes thanks to being protected by its tough cell wall. However, in order to fully utilize the nutrients and ingredients contained in chlorella, it was necessary to remove this cell wall.

Using Japan’s first revolutionary technology, Sun Chlorella succeeded in pulverizing over 90% of the chlorella cell wall.

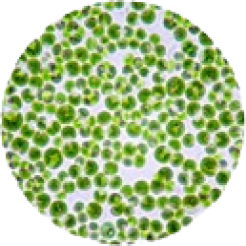

If you compare our chlorella with other companies by microscopic photos, the difference is obvious.

Photomicrograph(Sun Chlorella)

Photomicrograph(Other Chlorella)

Our unique cell wall pulverizing technology, without using any unnecessary chemicals or enzymes in the process, made it possible to break cell walls by physical mechanism. Thus, we can achieve high digestibility of chlorella without losing useful ingredients of chlorella.

Chlorella Digestibility Comparison

-

Sun chlorella “A” (Chlorella with cell wall pulverization)

-

Chlorella after making digestible (branching)

-

Untreated chiorella

Manufacturing environment to provide highly safe chlorella

Products that put safety first

In order to provide safe products and earn the trust of customers, Sun Chlorella, as a company involved in food industry, conducts operations that prioritize safety in terms of product quality and manufacturing processes.

In order to deliver chlorella products that are high in quality from safety to ingredients, we produce everything from raw materials to the final stage of the product under our management system.

Our absolute mission as a health food company is to keep strict production control and quality checks in all processes, and to continue making safe and high-quality products.

At Sun Chlorella, we will strive to further improve our product quality by providing products with even better safety and contributing to a healthy, long-living society.

Manufactured in a GMP certified factory.

Sun Chlorella A is manufactured in a GMP certified factory, certified by the Japan Health and Nutrition Food Association based on the Ministry of Health, Labour and Welfare’s February 2005 guidelines, “Regarding basic principles for the proper manufacture of food products such as tablets and capsules” and approved to display the mark on products.

GMP stands for Good Manufacturing Practice

GMP stands for Good Manufacturing Practice. It was established for the purpose of ensuring the quality and safety of products throughout the reception of raw materials to the shipment of the final products by the establishment of appropriate management organization, implementation (GMP software) of work management (quality control and manufacturing control) and construction of appropriate structural facilities (GMP hardware).

Acquisition of JHFA certification mark and safety self-assessment certification system.

In addition to acquiring GMP certification, we have also proactively acquired the Japan Health and Nutrition Food Association marks that regulate product standards such as ingredients contained in the food, as well as the safety self-assessment certification system (third party certification) established based on the recommendation “Report of the study meeting on securing health food product safety” on July 4, 2008.

Individual examination type JFHA (Health Functional Product)

The certification mark of “Japan Health and Nutrition Food Association” (JHFA) has been approved for use only by products that passed the Association’s rigorous review based on product specific standards.

Safety self-assessment certification system (third party certification)

It is a system in which, based on the findings at that time, the result of the safety self-inspection of health foods conducted by the manufacturing/selling business operator is audited by a third-party certification body (Japan Health and Nutrition Food Association) having no conflict of interest, which examines it objectively and grants the certification.